Micromachined scanning mirrors are interesting for a wide variety of

applications because of their potential low cost, high speed, low power

consumption, and reliability. These mirrors can offer significant

advantages over macro-scale mirrors, but the fundamental limitations of

scanning mirrors have not been widely discussed.

Miniaturization in electronic systems has led to radical improvements in

computers and communications, and micromachining technologies promise to

generate such improvements in miniaturized mechanical and optical

systems, including specifically higher-speed, smaller, lower-cost

scanning mirrors. Micromachined Mirrors provides an overview of the

performance enhancements that will be realized by miniaturizing scanning

mirrors like those used for laser printers and barcode scanners, and the

newly enabled applications, including raster-scanning projection video

displays and compact, high-speed fiber-optic components.

There are a wide variety of methods used to fabricate micromachined

mirrors - each with its advantages and disadvantages. There are,

however, performance criteria common to mirrors made from any of these

fabrication processes. For example, optical resolution is related to the

mirror aperture, the mirror flatness, and the scan angle.

Micromachined Mirrors provides a framework for the design of

micromirrors, and derives equations showing the fundamental limits for

micromirror performance. These limits provide the micromirror designer

tools with which to determine the acceptable mirror geometries, and to

quickly and easily determine the range of possible mirror optical

resolution and scan speed.

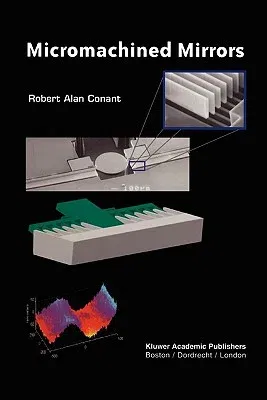

Micromachined Mirrors presents descriptions of mirrors made from two

fabrication processes - the surface-micromachining process and the

staggered torsional electrostatic combdrive (STEC) high-aspect ratio

micromachining process. The mirrors made using these two processes are

evaluated for scan speed, optical resolution, ease of manufacture, and

reliability.

Micromachined Mirrors also presents an example application of

surface-micromachined mirrors: a raster-scanning projection video

display. This demonstration shows the advantages of micromachined

mirrors (small high-speed scanners) with special attention paid to the

major drawback of surface-micromachined mirrors (lower resolution due to

dynamic deformation). The successful demonstration of this simple

prototype video display helps clarify the importance of the critical

performance characteristics to consider when designing micromachined

mirrors.